Achieve Excellence with Six Sigma

Driving Excellence with Six Sigma

Driving Excellence with Six Sigma

Every business owner strives for ultimate efficiency. You want minimal errors and maximum customer satisfaction. The powerful methodology known as Six Sigma helps achieve these goals. It provides a structured, data-driven approach. This method systematically eliminates defects and waste from processes. You can apply it to manufacturing or service industries equally. Implementing Six Sigma significantly improves your bottom line immediately.

Understanding the Six Sigma Goal

The term Six Sigma represents a statistical target primarily. Achieving Six Sigma quality means only 3.4 defects per one million opportunities. This level of near-perfection minimizes costly errors drastically. It requires sustained, precise process control consistently. You shift from simply fixing problems to preventing them entirely. This proactive stance ensures superior quality output always. Businesses worldwide have adopted this methodology successfully.

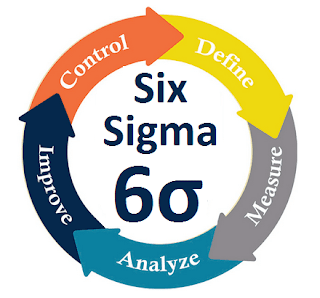

The DMAIC Framework

You execute Six Sigma projects using a five-phase roadmap. This framework is called DMAIC. Each letter represents a crucial step in the process.

D – Define: You must first clearly define the problem. Identify the process that needs improvement quickly. Determine the project goals and customer requirements clearly. For example, a restaurant defines an order error rate of 10%.

M – Measure: Next, you gather data on the current process performance. Establish a baseline metric for the existing error rate accurately. Collect accurate data consistently over time. This step allows you to quantify the magnitude of the problem.

A – Analyze: You then examine the collected data thoroughly. Use statistical tools to identify the root causes of defects. Determine why the process fails to meet customer expectations. Do not just treat the symptoms superficially. Instead, dig deep for underlying systemic issues.

I – Improve: Now, develop and test potential solutions actively. Implement changes designed to eliminate the root causes effectively. Pilot these solutions on a small scale first. Verify that the implemented changes truly solve the problem permanently.

C – Control: Finally, you must standardize the improved process entirely. Implement monitoring systems to sustain the gains achieved. Establish metrics to ensure the process does not revert back to the old ways. Document the new, successful procedures clearly. This standardization step completes the cycle.

Benefits for Your Business

Applying the Six Sigma methodology provides numerous advantages. These benefits directly impact your operational health and market standing.

Higher Quality and Fewer Defects: This primary outcome reduces waste substantially. You spend less money on fixing mistakes or scraping materials. Customers receive exactly what they expect consistently.

Cost Reduction: Minimizing errors directly lowers operational costs significantly. Less rework means lower labor and material expenses dramatically. Efficient processes utilize resources optimally every time.

Increased Customer Satisfaction: Delivering consistent quality delights your customers repeatedly. Satisfied customers become loyal advocates for your brand readily. This word-of-mouth promotion reduces marketing expenses significantly. Customer loyalty also leads to repeat business reliably.

Improved Efficiency and Cycle Time: Analyzing processes removes unnecessary steps successfully. This streamlining speeds up product delivery or service provision. Faster turnarounds give you a competitive advantage immediately.

Data-Driven Decision Making: Six Sigma removes reliance on guesswork or intuition entirely. You base all process changes on hard data and statistical analysis. This scientific approach leads to more reliable, predictable outcomes always.Implementing Six Sigma Successfully

Starting your Six Sigma journey requires commitment from leadership first. Train key employees in the DMAIC methodology effectively. Identify process champions who will lead improvement projects actively. Begin with small, manageable projects that offer quick wins. Success builds momentum and buy-in among staff quickly. Focus on areas directly impacting customer pain points initially. Remember, this is a continuous cultural shift, not a quick fix. You will build a more resilient, higher-performing business over time.

This Post Has 0 Comments